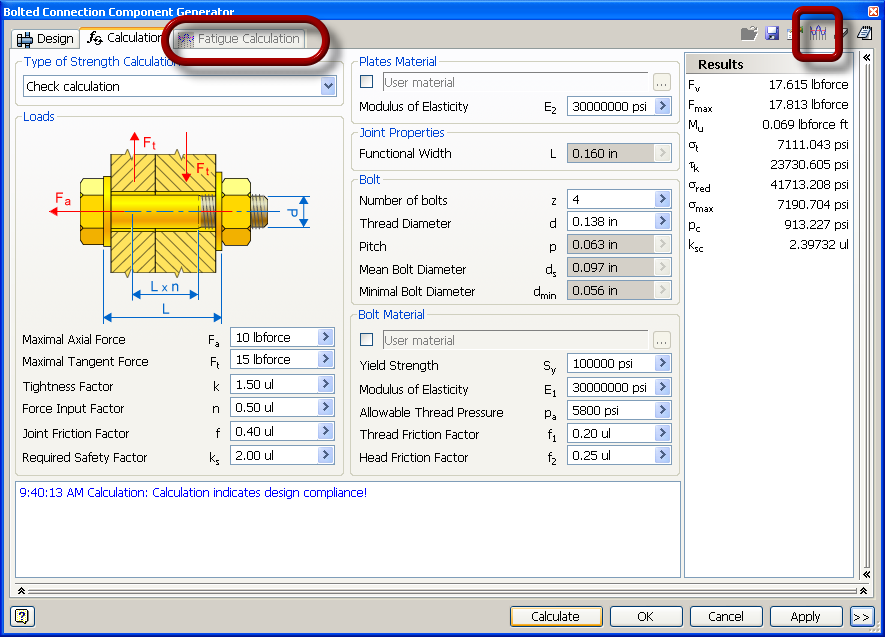

ASML Bolt Calculator

At ASML, as part of a relatively new standard, each and every bolt in an assembly must be assigned a specific torque. One of my first assignments was to change the material of all of the bolts in an old assembly, and assign a torque spec to each bolt. Normally the ASML bolt calculator is used for one or two connections at a time, in my case, over 100 connections needed to be analyzed. Additionally, the official ASML bolt calculator does not include thermal planar loads due to CTE mismatch between the bolted materials. Calculating these loads one at a time can be very time consuming and prone to human-error.

Noticing this array of problems, I took the initiative to innovate and deliver a highly automated add-on to the original calculator. This saves the designer, and the reviewer, time and headache while reducing the chance of mistakes passing by unnoticed. This add-on utilizes two customized VBA scripts that I wrote, as well as an additional calculator to solve for the estimated planar load due to CTE mismatch–which historically has been done using time-consuming and error-prone FEA. My solution allows the designer to view the details for all of the bolted connections on one screen, facilitating quick review of inputs to catch any mistakes. Now, sweeping changes can be made to the bolted connections in an assembly in a matter of minutes, rather than hours or even days.

These changes have been unofficially adopted by the calculator’s maintaining team and are being offered to designers who need to make large scale changes to the bolted joints in an assembly. I also created self-guided training materials that ensure users can be effective with the add-on in only 15 minutes. Thanks to my efforts, the time savings of somebody making extensive bolt-related changes, as I have, can easily be upwards of 100 man-hours.

Inert Gas Optomechanical Enclosure

In order to test a piece of equipment that gets incorporated into the final machine, an optomechanical assembly, within an inert gas enclosure, is needed. I designed such an enclosure, sourcing optomechanical components from Thorlabs in order to create a cohesive, high-precision system. Sourcing from Thorlabs facilitated a rapid design process, and the use of standard components will make servicing the system in the field quick and easy. Alongside the inner optomechanical assembly, I designed the airtight enclosure with components sourced from McMaster Carr, and coordinated the system’s review with various internal experts.

Hose Rerouting and Fitting Simplification

I received a project-in-progress that was handled by a former colleague; rather than taking it and finishing it as is, I convinced management to let me rework the solution. It added a few weeks to the overall delivery date of the project, but through cost-of-goods and labor savings, the project went from an estimated $100,000 per year increase, to $400,000 per year in savings. This solution was also thousands of times cleaner due to the removal of an aggressively outgassing material. This cleanliness increase was great as it directly affected one of the most critical and sensitive portions of the machine.

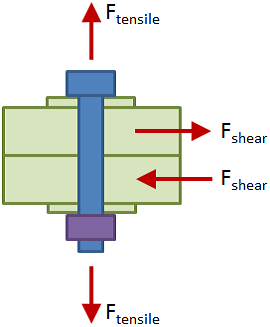

Optomechanical Clamps

I reworked a submodule of the machine that was experiencing serious, expensive failures, largely due to inadequate optomechanical clamps used to locate and protect optics within the system during shipping. My analysis of and alterations to the bolted connections and optomechanical clamps guided a budget-driven redesign. As a result of my attention to detail on this project, the altered submodule is expected to save ASML approximately $400,000 in quality issues annually.

Other Calculators

I’ve created and improved numerous calculators during my time at ASML, and have compiled a small database of them. I’ve taken the official ASML flexure calculator and added additional support for L-shaped flexures by utilizing Castigliano’s theorem. I’ve also added quick and easy material selection to this calculator to remove another source of human error and to save the designer the inconvenience of looking up material properties in a material database. I’ve also created personal calculators for O-ring compression, enclosure gas-purge cycle time, and a calculator for friction cone analysis for optical assemblies.